Rare Earth Supply Chain Issues Hamper Tesla's Optimus Robot Development

Table of Contents

The Critical Role of Rare Earth Minerals in Robotics

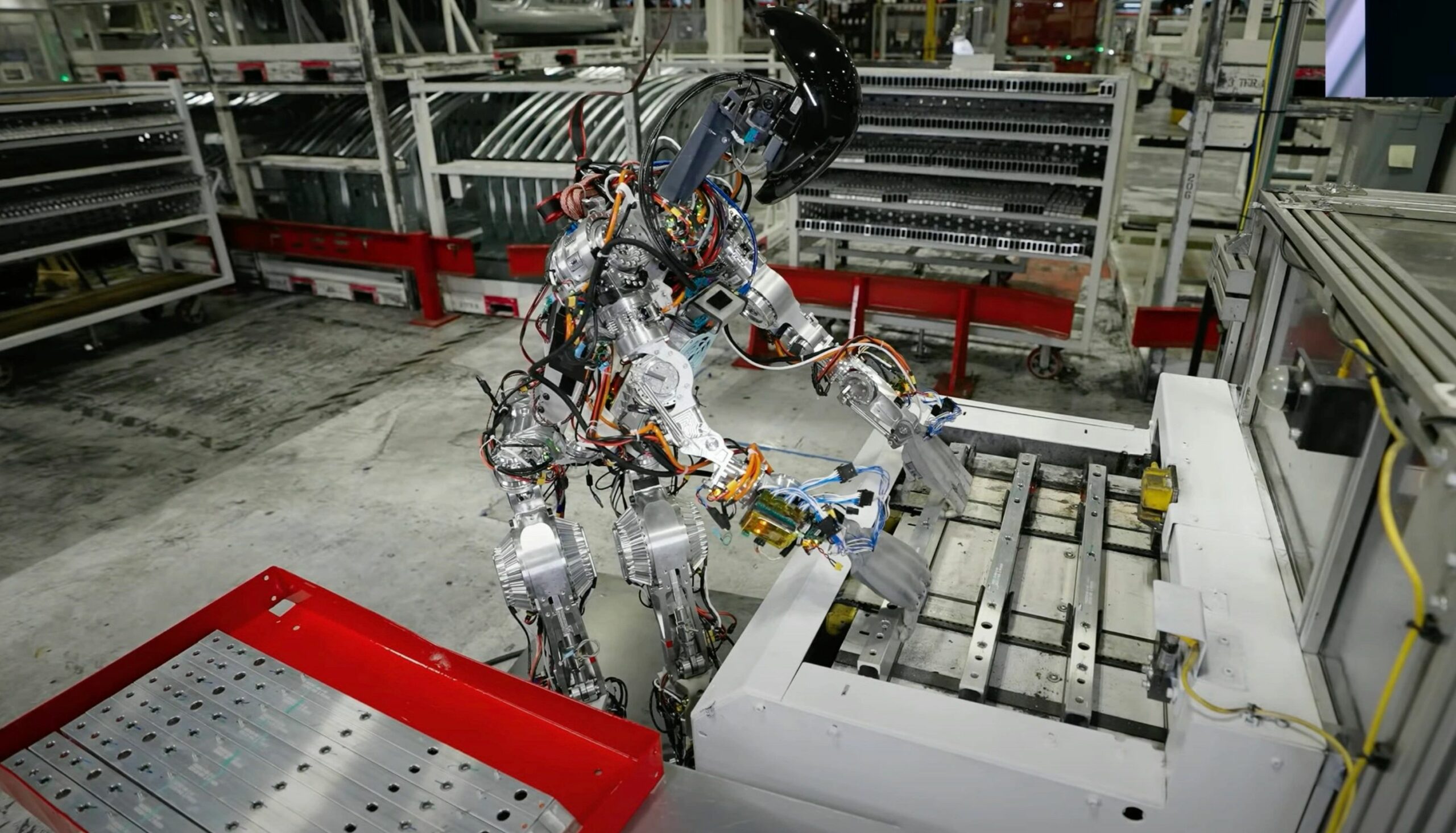

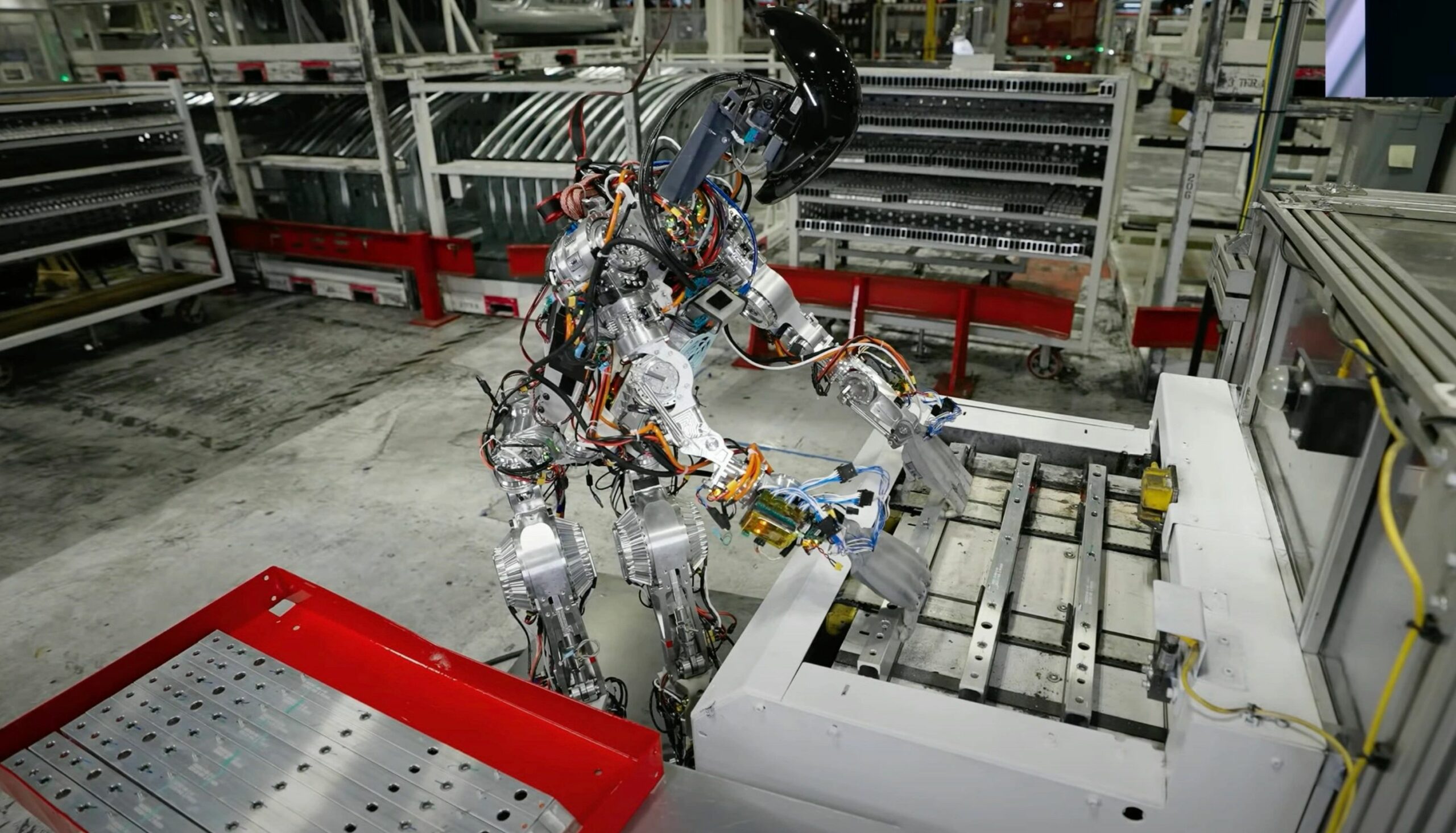

The smooth, efficient movements of robots like Optimus rely heavily on powerful and precise motors and actuators. These components are almost universally dependent on rare earth magnets, specifically those utilizing neodymium, dysprosium, and praseodymium. These rare earth elements (REEs) possess unique magnetic properties far exceeding those of other materials, making them irreplaceable in many high-performance applications.

- Unique Magnetic Properties: REEs offer exceptionally high magnetic strength and temperature resistance, crucial for robots operating in diverse environments.

- Irreplaceable in many applications: Current alternatives lack the power-to-size ratio and temperature stability required for sophisticated robotics.

- Robot Components Relying on Rare Earth Magnets:

- Motors for locomotion and manipulation

- Actuators for precise movements

- Sensors and positioning systems

- Grippers and other end-effectors

Keywords: Rare earth magnets, robotics, neodymium magnets, dysprosium magnets, actuator, motor.

Current State of the Rare Earth Supply Chain: Bottlenecks and Geopolitical Factors

The global rare earth supply chain is characterized by significant geographical concentration, with China holding a dominant position in both mining and processing. This concentration creates considerable geopolitical risks and vulnerabilities.

- China's Dominance: China controls a vast majority of the global REE supply, leading to concerns about potential supply disruptions.

- Geopolitical Implications: Trade disputes, sanctions, and resource nationalism can severely impact the availability and price of REEs.

- Environmental Concerns: Stricter environmental regulations in mining and processing operations can lead to further supply constraints.

- Key Challenges in the REE Supply Chain:

- Limited mining capacity outside of China

- Processing bottlenecks due to technological complexities and environmental concerns

- Transportation and logistical issues impacting delivery times and costs

Keywords: Rare earth mining, China, geopolitical risks, supply chain disruptions, trade wars, environmental regulations.

Impact on Tesla's Optimus Robot Production Timeline and Costs

The scarcity and price volatility of rare earth elements directly impact Tesla's ability to produce Optimus robots at scale. This translates to several significant challenges:

- Production Delays: Shortages of critical REEs can cause significant delays in the robot's production timeline, pushing back its market entry.

- Increased Manufacturing Costs: Fluctuating REE prices directly impact Tesla's manufacturing costs, potentially affecting the robot's final price and profitability.

- Supply Chain Risks: Dependence on a single or limited number of suppliers exposes Tesla to significant risks, including geopolitical instability and price manipulation.

- Potential Mitigation Strategies:

- Diversification of sourcing to reduce reliance on a single supplier.

- Investment in research and development of alternative materials.

- Implementation of robust supply chain risk management strategies.

Keywords: Tesla Optimus production, delays, manufacturing costs, supply chain risks, alternative materials, cost optimization.

Potential Solutions and Future Outlook for Tesla and the Robotics Industry

Addressing the challenges posed by the rare earth supply chain requires a multi-pronged approach focusing on sustainability and diversification:

- Investment in Responsible REE Mining and Processing: Promoting ethical and environmentally sound mining practices is crucial for long-term supply security.

- Recycling and Urban Mining: Recycling end-of-life electronics and extracting REEs from urban waste streams can significantly increase supply.

- Developing Alternative Materials and Technologies: Research and development of alternative materials with comparable magnetic properties can reduce reliance on REEs.

- Industry Collaboration: Collaboration among stakeholders across the robotics industry can foster innovation and efficient resource management.

Keywords: Sustainable REE mining, recycling, alternative materials, robotics industry, future of robotics.

Conclusion: Navigating the Rare Earth Challenge for Tesla's Optimus Robot

The development of Tesla's Optimus robot is inextricably linked to the stability and sustainability of the rare earth supply chain. The current concentration of REE mining and processing, coupled with geopolitical factors, presents significant challenges to the robot's production timeline and cost. However, by embracing sustainable mining practices, investing in recycling and alternative materials, and fostering industry collaboration, Tesla and the wider robotics industry can navigate these challenges and ensure a sustainable future for this transformative technology. Understanding the complexities of the rare earth supply chain is crucial for the future success of innovative projects like Tesla's Optimus robot. Learn more about the challenges and potential solutions to ensure a sustainable future for robotics. Keywords: Rare earth supply chain, Tesla Optimus, robotics future, sustainable solutions.

Featured Posts

-

The Closure Of Anchor Brewing Company 127 Years Of Brewing History

Apr 24, 2025

The Closure Of Anchor Brewing Company 127 Years Of Brewing History

Apr 24, 2025 -

Microsoft Activision Deal Ftcs Appeal And Its Implications

Apr 24, 2025

Microsoft Activision Deal Ftcs Appeal And Its Implications

Apr 24, 2025 -

Indias Booming Stock Market Whats Fueling Niftys Impressive Growth

Apr 24, 2025

Indias Booming Stock Market Whats Fueling Niftys Impressive Growth

Apr 24, 2025 -

Navigating The Chinese Market Challenges Faced By Bmw Porsche And Other Automakers

Apr 24, 2025

Navigating The Chinese Market Challenges Faced By Bmw Porsche And Other Automakers

Apr 24, 2025 -

Luxury Car Sales In China Analyzing The Difficulties Faced By Brands Like Bmw And Porsche

Apr 24, 2025

Luxury Car Sales In China Analyzing The Difficulties Faced By Brands Like Bmw And Porsche

Apr 24, 2025