The Limits Of Robotics In High-Precision Sneaker Manufacturing: A Case Study Of Nike

Table of Contents

The Intricacies of Sneaker Construction

High-end sneakers, especially those produced by Nike, are not simply shoes; they are complex, multi-material constructions requiring a high degree of precision. Understanding the intricacies is crucial to grasping the challenges faced by robotics in this sector. Consider the typical components: premium leather, breathable mesh fabrics, reinforced synthetic overlays, intricate stitching patterns, and specialized adhesives. These materials possess vastly different properties, demanding specialized handling techniques.

The dexterity required for the assembly process is remarkable. Tasks such as stitching uppers, precisely gluing the midsole and outsole, and applying intricate overlays demand fine motor control and adaptability currently beyond the reach of most robotic systems. This intricate process involves numerous steps and components, each requiring careful manipulation and placement.

- Varied material properties demanding adaptable robotic grippers. Different materials require different gripping pressures and techniques to avoid damage.

- Precise stitching requiring fine motor control surpassing current robotic capabilities. The precision and consistency required for stitching are difficult to replicate robotically.

- Complex assembly processes involving numerous steps and components. Coordinating multiple robotic arms for a seamless assembly is a significant engineering challenge.

- Need for human inspection to ensure quality control. Even with automation, human eyes remain essential for detecting subtle defects.

Current Robotic Capabilities and Limitations in Sneaker Manufacturing

While robotics has found applications in the footwear industry, primarily in automated cutting and material handling, its role in the intricate assembly of high-precision sneakers remains limited. Current robotic systems excel at repetitive tasks involving simple geometry and uniform materials. However, the nuanced requirements of sneaker manufacturing present significant hurdles.

The limitations stem from several factors:

- Lack of adaptability in robotic grippers for diverse materials. Existing grippers struggle to handle the variety of textures and sensitivities found in sneaker components.

- Inconsistent pressure and precision in gluing and stitching applications. Achieving the consistent pressure and precision required for reliable bonding and stitching is difficult to achieve robotically.

- High programming costs and complexity for intricate tasks. Programming robots for complex, multi-step assembly processes is expensive and time-consuming.

- Difficulties in handling unexpected variations in material properties. Robotic systems often struggle with variability in material thickness, texture, or consistency.

The Role of Human Skill and Craftsmanship

Despite advancements in automation, the value of human skill and craftsmanship in high-precision sneaker manufacturing remains irreplaceable. The nuanced judgment and problem-solving capabilities of skilled workers are crucial throughout the production process. Humans excel at tasks requiring adaptability, precision, and quick decision-making.

The unique contributions of human workers include:

- Quality control and defect detection. Human inspectors can identify subtle flaws that robotic vision systems might miss.

- Adaptive problem-solving during the manufacturing process. Skilled workers can quickly adapt to unexpected issues and find solutions.

- Precision hand-stitching and finishing. The fine motor skills needed for intricate stitching and finishing remain unmatched by robots.

- Maintaining consistency in high-quality craftsmanship. Human workers can maintain a level of consistent quality difficult to achieve through automation alone.

Cost-Effectiveness and Return on Investment (ROI) of Robotics in Sneaker Manufacturing

Implementing advanced robotic systems in sneaker manufacturing requires a substantial initial investment. The high capital expenditure for robotic arms, grippers, and sophisticated control systems poses a significant barrier to entry. Further costs include programming, maintenance, and potential downtime.

Comparing the cost-effectiveness of robots versus human labor depends on several factors, including production volume, the specific tasks being automated, and the cost of labor. While robots can potentially reduce labor costs in some areas, these savings might be offset by the high initial investment and ongoing maintenance costs.

- High capital expenditure for robotic systems. The initial investment for advanced robotics is substantial.

- Programming and maintenance costs. Ongoing programming and maintenance add to the total cost of ownership.

- ROI considerations for different production volumes. ROI is heavily influenced by the scale of production.

- Potential for reduced labor costs, offset by other expenses. Labor savings might be negated by other robotic-related costs.

Future Innovations and Potential Breakthroughs

While current limitations are significant, ongoing advancements in robotics and AI hold the promise of overcoming these challenges. Future innovations could significantly expand the role of robots in high-precision sneaker manufacturing.

Potential breakthroughs include:

- Development of more sophisticated robotic grippers. Grippers capable of adapting to a wider range of materials and textures are crucial.

- Improved AI-powered vision systems for quality control. Advanced vision systems can enhance defect detection and improve quality control.

- Advancements in force sensing and control for precise manipulation. Improved force sensing will allow robots to handle delicate materials more effectively.

- Collaborative robots (cobots) working alongside human workers. Cobots can assist human workers, improving efficiency and reducing strain.

Conclusion

This case study of Nike demonstrates that while robotics is transforming many aspects of manufacturing, its application in high-precision sneaker production faces significant obstacles. The complex nature of sneaker construction, coupled with the high value of human craftsmanship and the significant investment required for advanced robotics, currently limits widespread robotic automation. However, future advancements in robotics and AI hold the promise of bridging these gaps. Continued research and development in areas like AI-powered dexterity and advanced sensor technology are crucial to expanding the role of robotics in sneaker manufacturing. Further investigation into the cost-effectiveness and ROI of specific robotic implementations within the sneaker manufacturing process will guide future investments in this field. Therefore, a balanced approach combining human expertise with carefully selected robotic technologies remains the key to producing high-quality, high-precision sneakers for the foreseeable future. For a deeper understanding of the intersection between technology and craftsmanship in the sneaker industry, continued exploration of the robotics in sneaker manufacturing field is vital.

Featured Posts

-

Trump Administration Threatens Harvard With 1 Billion Funding Withdrawal

Apr 22, 2025

Trump Administration Threatens Harvard With 1 Billion Funding Withdrawal

Apr 22, 2025 -

The Pan Nordic Army A Combined Strength Of Swedish Tanks And Finnish Troops

Apr 22, 2025

The Pan Nordic Army A Combined Strength Of Swedish Tanks And Finnish Troops

Apr 22, 2025 -

Higher Bids Higher Risks Stock Investors Face Continued Market Uncertainty

Apr 22, 2025

Higher Bids Higher Risks Stock Investors Face Continued Market Uncertainty

Apr 22, 2025 -

Fsus Post Shooting Class Resumption Plan A Controversial Decision

Apr 22, 2025

Fsus Post Shooting Class Resumption Plan A Controversial Decision

Apr 22, 2025 -

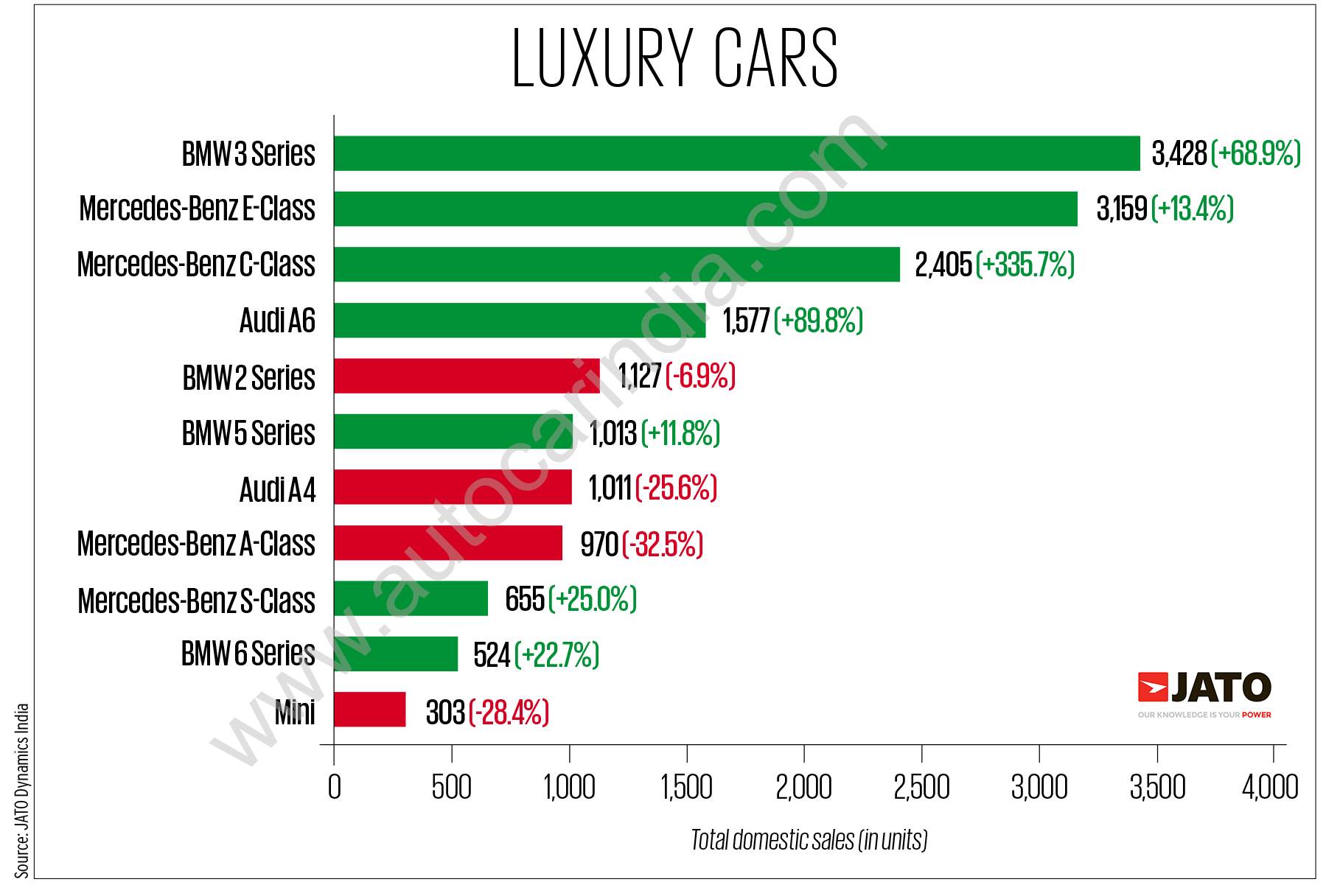

Luxury Car Sales In China Bmw Porsche And The Bigger Picture

Apr 22, 2025

Luxury Car Sales In China Bmw Porsche And The Bigger Picture

Apr 22, 2025